Many of us have an inexplicable fascination for the underwater part of a ship. We rarely get to see it, but we always know that massive, menacing propeller is lurking just below the surface, like a sea monster.

And while most of us will never get anywhere near it, for some people a submerged hull is a daily workplace. Mr. Fred Noordman is one such person – an experienced diver himself, his company FN Diving provides underwater repair, maintenance and inspection services in Rotterdam. He has kindly agreed to meet with me and provide firsthand insight on what this fascinating job entails.

The Shipyard: You get a call from a client that their ship has a damage. What is the first thing you do?

Fred Noordman: Underwater ship repair is a precise job that starts with the indication of the problem. This indication could be a certain noise or vibration, for example, telling us that there is something wrong with the propeller. As one of the most expensive and necessary parts of the vessel, it is crucial that any damage to the propeller is discovered and repaired quickly. Having a ship with a dysfunctional propeller is like having a big car with no wheels.

After we analyze the indications, the step that follows is thorough underwater inspection. The inspection is followed by writing up a complete damage report, describing the exact location and level of the damage involved. Depending on each specific case, we have multiple options how to solve the problem. In most cases we decide which option is best and most cost effective in the long term.

The Shipyard: Why underwater repair and not dry dock?

Fred Noordman: Taking a ship into dry dock can be very expensive and time-consuming. The ship has to be unloaded, taken into the dry dock, repaired, and then floated out again. If no dry dock is available at the moment, there is additional waiting time before work can begin. This lengthy procedure takes valuable time out of the ship’s sailing schedule, losing the shipping company money.

At the same time, if the ship has a noticeable damage, it is very important to fix it as soon as possible. For instance, damaged propellers can cause vibrations, secondary cavitation and additional loads on the engine, all of which eventually result in increased fuel consumption. Even a bend in one blade only, can cause enough disbalance in the pressure distribution of the propeller to lead to an engine overload. That is why underwater ship repair is optimal in many cases. It is a cost-effective method which allows the ship to continue its in-port loading operations so that it can sail on time.

Underwater repair is very important, because even if a damage is not having any effect on your ship at that precise moment, it can produce so much secondary cavitation on your rudder later on, that the cost to repair the initial damage is only a fraction of the costs you will have later on in dry dock.

The Shipyard: What methods of underwater repair are there?

Fred Noordman: The method we use depends on the type of damage we discover. Sometimes we find cracks, grinds and nicks in propellers, caused by hitting sand or foreign objects in the water. Sometimes an entire blade is bent or is missing a part. Depending on the hydrodynamic properties of the propeller, some of these damages can often be fixed using hydrodynamic reshaping.

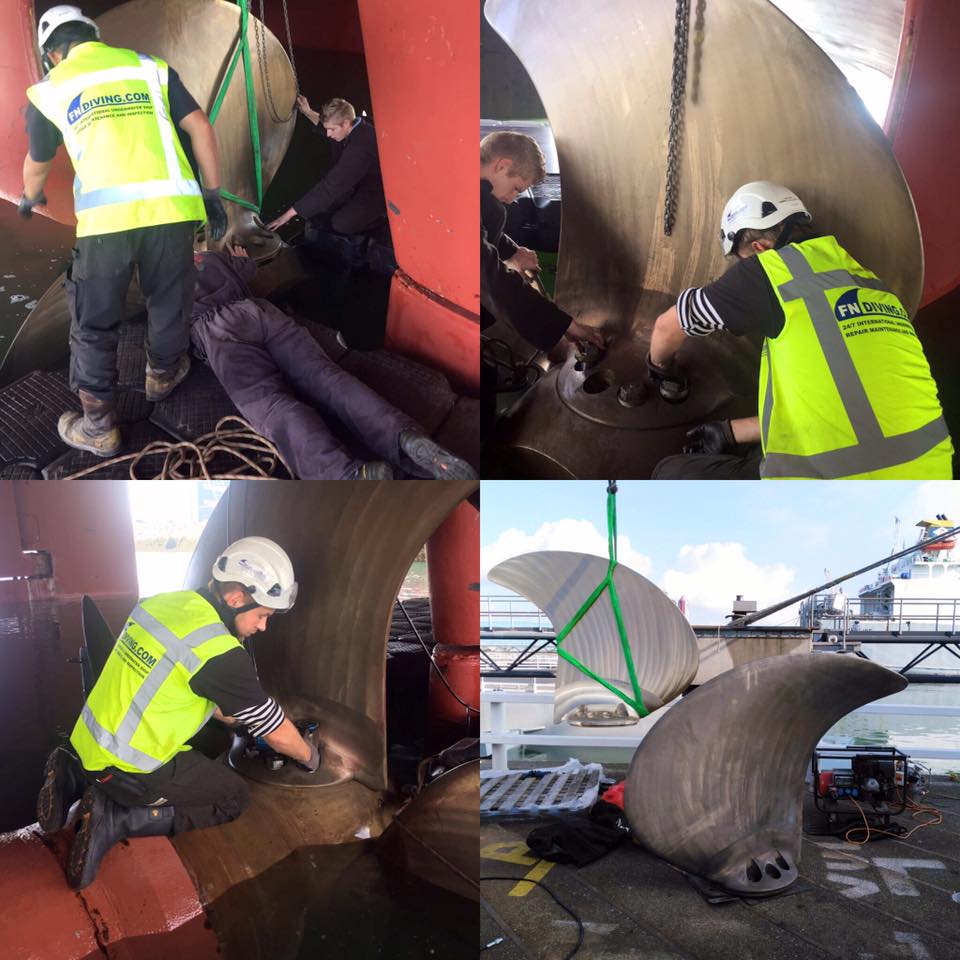

One of the methods we use is straightening. For example, if a propeller has bent blades, we can fix them in the water using our cold static load press machines, ranging from 50 tons to 250 tons. In certain cases, you are missing entire pieces of the blade and this can cause a serious disbalance in the propeller. In such cases straightening is not an option anymore, and we have to weld on the missing pieces to fix the disbalance. If we do not have time to weld new tips or blades, we can resort to cutting. In this case, underwater diamond-cutting machines are used to crop off the damaged blade area.

When we have a controllable pitch propeller, we sometimes take the whole blade off and we metallurgically repair it on land if the time allows it. Other times we take the entire propeller off while the ship is in the water, repair it in the workshop, and then mount it back on. When we take off a whole blade or the entire propeller, we sometimes use big flexible pontoons or buoys to trim the ship. This means that we put 70 tons of extra buoyancy weights underneath the ship to lift it out of the water, allowing us to carry out our repairs. We can also make a special balloon in the water around the area that needs to be repaired. This way, the diver can go into the balloon and take the blades off in a dry environment while the ship is in the water. This method can also be applied to take out entire bow thrusters, to exchange separate thruster blades, or to repair and change seals.

Besides repairs of the propeller and the thrusters, we can also do underwater metallurgic welds and hull repairs. We set up a special cofferdam around the damaged hull-plating, giving us a dry environment, then we cut out the damaged steel plating and replace it with a new one. There are different cofferdams to fit various hull types. This way, we can also do overboard repairs, allowing us to insert a complete new piping system into the hull when needed.

The Shipyard: What type of damage cannot be repaired in the water and requires a dry dock?

Fred Noordman: I always say you have to look at the cost-effectiveness. If you do an inspection and the propeller is almost completely damaged – for example over 80 percent – then you might consider unloading the vessel to take the whole propeller off and take it to land, instead of repairing it in the water. Also, if you are close to an intermediate five-year dry-docking survey of the vessel anyway, you might just as well go into dry dock and do the repairs there. Technically, we can do most repairs in the water, but it is the economic calculation that determines whether going into dry dock isn’t a better option.

The Shipyard: How many ships do you inspect per year?

Fred Noordman: We see about 300 ships underwater every year.

The Shipyard: How many people dive down on one job?

Fred Noordman: Typically, one person is all it takes. We can take out a 50-ton thruster with one diver.

The Shipyard: What is the most challenging part about working underwater, compared to working on land?

Fred Noordman: For starters, working underwater near a huge floating machine is a potentially deadly environment. Working in such an environment requires a high degree of discipline, endurance, and concentration. Another challenging thing is that the jobs we do usually happen during cargo operations in port, where many different factors have to be considered: dealing with agents and port authorities, weather conditions, getting the right technicians to show up at the right time and place, changing schedules of ships, planning and adjusting our own schedule accordingly, etc.

The Shipyard: What are some of the safety procedures in place when divers are working on a ship?

Fred Noordman: We have special quality assurance and health procedures. First and foremost, safety starts with yourself and with a common goal. The repair of the ship is never worth somebody’s life. Second, it is all very procedural work so there are many on board as well as many in house safety regulations put in place which we follow strictly. In addition, diving is a very regulated job and before you can become a diver you have to pass a 50 000 EUR diving course.

The Shipyard: What does it take to be a successful ship-repair diver?

Fred Noordman: This is not a simple job, but a tough one, to which you have to commit a lot of your time. To perform well, you have to be very fit, both mentally and physically. Sometimes you get called on an urgent job in the middle of the night, and you have to be prepared to leave your bed, run out, and do what needs to be done. Some of our operations take up to 40 hours without a break, and we have to finish on time because the ship has to go. We have both male and female divers, who all perform very well on the job.

To be successful, you have to be passionate and put your heart into it to make it work. You should never underestimate the job.

The Shipyard

P.S. Keep scrolling for some more awesome photos of the job.